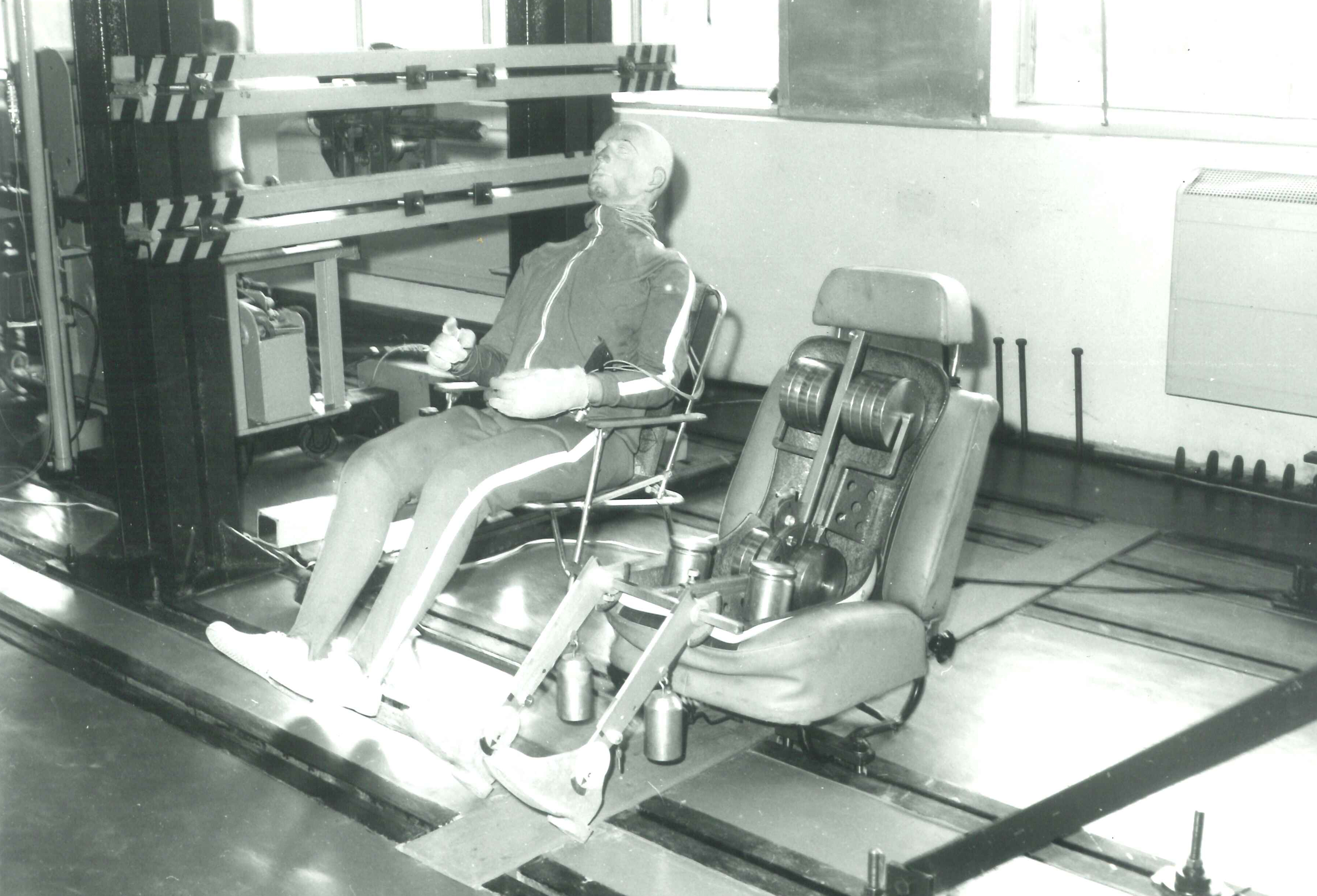

What does FODRŠAMARUPUSOPR mean?

“The test track and all the necessary equipment were built and constructed by the ÚVMV staff practically by themselves,” says Tesárek. They also designed and tested the propulsion device themselves - a steam rocket that was used to accelerate the car to the required test speed. At the time, the basic apparatus for the test consisted of a water tanker and a diesel-powered electric generator. The rocket’s tank was first filled with water, which was transformed into high-pressure steam by means of electric heating coils, and when the desired temperature and pressure were reached, the rocket nozzle was mechanically opened and the steam – with a very loud hiss – propelled the rocket forward. The vehicle was thus accelerated by force from the rear. The whole assembly (vehicle, rocket) was guided directionally by a rail, which ended about 5 metres from the concrete wall. At its end, the steam rocket hit a wedge brake, which stopped it while the car continued forwards.

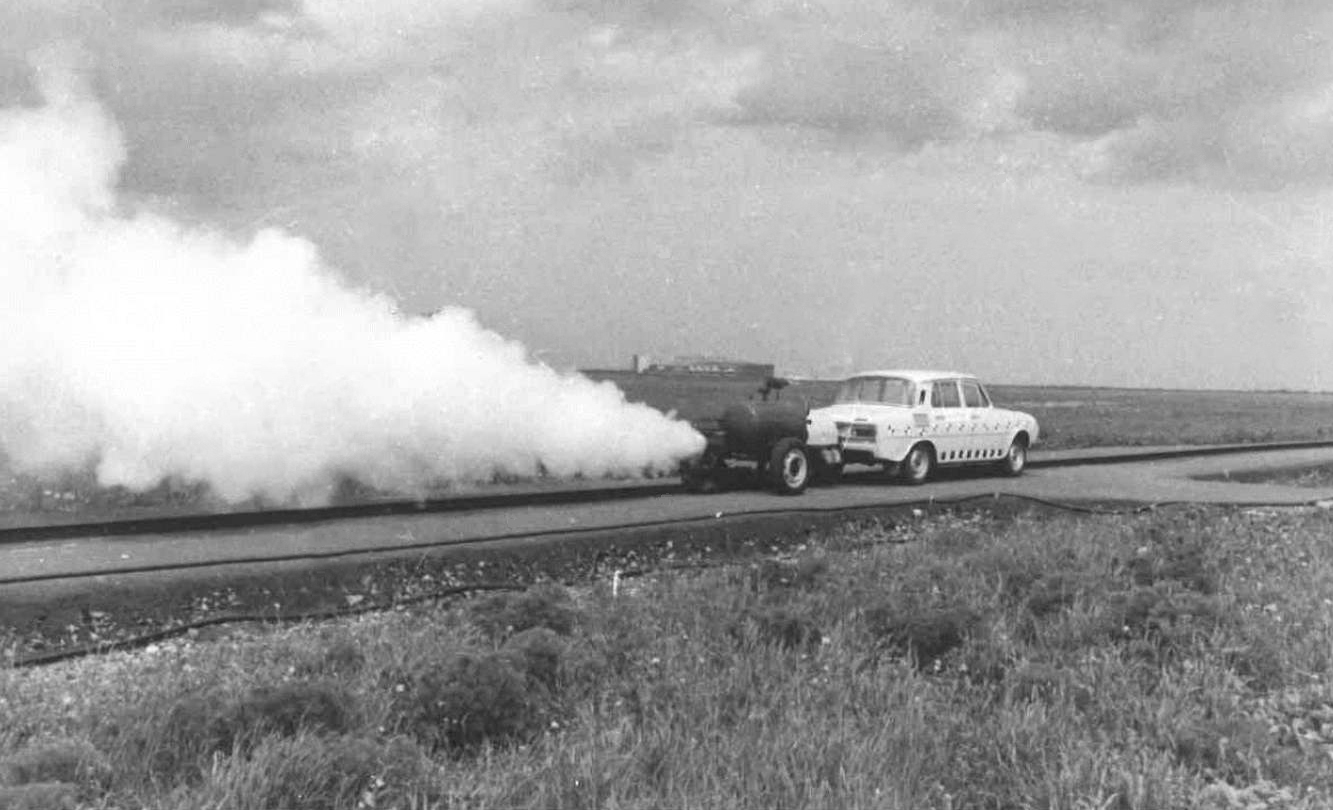

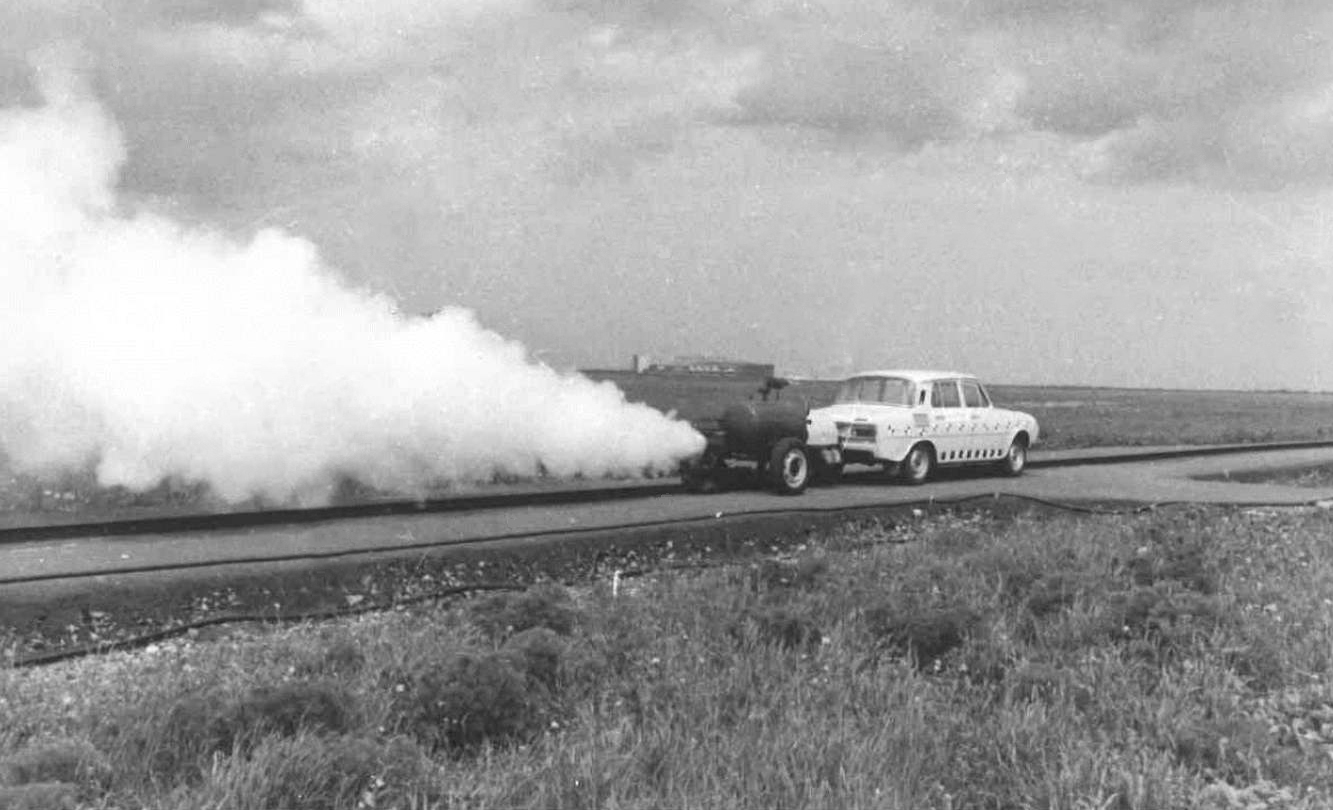

Behind the car is the original steam rocket used to accelerate cars to the required test speed.

Behind the car is the original steam rocket used to accelerate cars to the required test speed.

Two versions of this device can be seen in period photographs: the HRB-01 and later the HRB-02. As the device was dogged by considerable variations in cold periods due to heat loss, the staff of the Security Group of the Central Ministry of Defence later fitted the rocket with insulation and cladding, thus creating the HRB-02 version (Hot Water Rocket of the Security Group of the Central Ministry of Defence). In addition to that name, this version bore another interesting inscription, namely: FODRŠAMARUPUSOPR, that immortalises the team members (FOgl, DRmota, ŠAtochin, MAjetič, RUblič, PUčálka, SOuček, PRažák).

The HRB-2 rocket with the designation FODRŠAMARUPUSOPR, a contraction of the names of the ÚVMV team.

The HRB-2 rocket with the designation FODRŠAMARUPUSOPR, a contraction of the names of the ÚVMV team.

“All we have today, unfortunately, is a replica of the rocket – the original one was stolen when the research centre relocated,” says Tesárek. The first car to pass the homologation test was a yellow ŠKODA 100 in May 1972. The car had to be propelled against a fixed obstacle at a speed of 48.3 km/h with a tolerance of about plus five kilometres per hour. The speed was determined by empirically determined formulas and the experience of the test engineers at the time. The basic parameters for the calculations were the weight of the vehicle, the amount of water and the saturated steam pressure. Once the required parameters had been calculated, the staff had to verify the results in practice, and several test runs were carried out in the opposite direction of the test track before the actual test. During these tests, a driver was seated in the vehicle and stopped it at the end of the runway (the rocket was also stopped here by a wedge-type brake).

During a test, the rocket propels the car from the rear down the test track.

During a test, the rocket propels the car from the rear down the test track.

French inspectors from the French counterpart institution, UTAC (now UTAC Ceram) were present at the first test. The day before their arrival, the ÚVMV staff carried out a rehearsal with a used car, and on the second day, after preparations that lasted through the night, the test proper was carried out in the presence of the foreign inspectors. The test was filmed by a high-speed camera, of course, on classic 35mm film. The evaluation, i.e. the assessment of whether the movement of the steering column during the impact was “within the norm”, could thus only take place some time after the test, after the film had been developed and processed. The ŠKODA passed the test.

A ŠKODA 100 on the test track at Prague airport.

A ŠKODA 100 on the test track at Prague airport.