In recent years, the number of control units, sensors and electronic devices in new cars has increased significantly. The specific number depends on the customer’s wishes and car configuration, and there are so many possible combinations that they cannot even be tested in conventional prototypes. In addition, before the first prototypes are launched, the developers must ensure that the basic functions controlled by the electronics, including the brakes, will work. That is why our Technical Development department, in cooperation with Digiteq Automotive, uses special test stands to verify the functions of electronics.

Integration tests for the ENYAQ iV require three “breadboards” and one HiL.

Integration tests for the ENYAQ iV require three “breadboards” and one HiL.

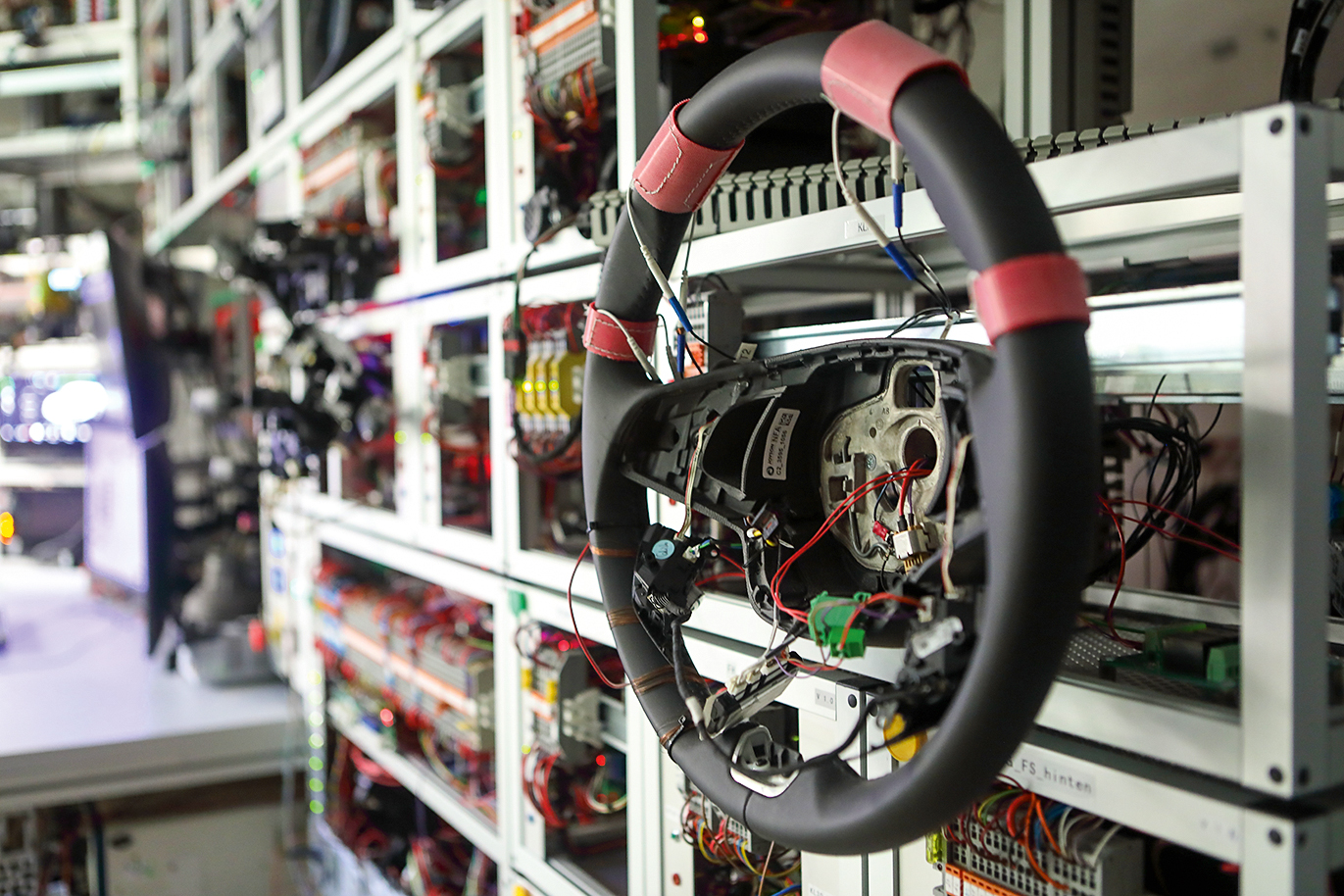

They are called HiL (Hardware-in-the-Loop) and breadboard. The former is used to test the functionality that the control units create, and the latter focuses on testing the functionality of data communication among control units. To the layman’s eye, both test conditions look basically the same: They are workstations where all the car’s (low-voltage) electronics are mounted in frames.